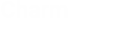

Wood brushing is one of the frequently used techniques of decorative finishing of wooden objects. It is based on varying degrees of hardness of the layers of wood. The cross section clearly demonstrates the circles of the year, which form different fibers according to their physical characteristics. Depending on the type of wood, the layers form a unique pattern that adorns any product or interior item.

When removing soft layers, areas with hard fibers show a clear relief on the surface of the wood, giving it a special decorative effect. In the natural environment, this happens over time: the soft fibers independently leave, depending on the frequency of use of the object. Brushing gives texture to wood, creating the effect of visual aging.

When removing soft layers, areas with hard fibers show a clear relief on the surface of the wood, giving it a special decorative effect. In the natural environment, this happens over time: the soft fibers independently leave, depending on the frequency of use of the object. Brushing gives texture to wood, creating the effect of visual aging.

Brashirovanie as a technique of artificial aging of wood

This method of structuring is suitable for working with hard and soft wood species with a clearly defined texture and manifesting layers of different hardness.These include oak, pine, walnut, wenge, ash, larch.

Rocks with small fibrous, poorly pronounced texture are not suitable for brushing. This is wood of maple, teak, alder, beech, cherry, birch.

Rocks with small fibrous, poorly pronounced texture are not suitable for brushing. This is wood of maple, teak, alder, beech, cherry, birch.

The brushing technique involves the creation of incredibly beautiful, original textures that are ideally suited for interior objects of various styles. Structured wood is actively used in the manufacture of furniture, floors, decorative parts.

Equipment for brushing

Brushing is considered a simple and affordable technique that allows you to quickly achieve the effect of aged natural wood. To do this, you need a home workshop and a minimum set of tools:

- metal brushes with different stiffness, which remove the soft fibers from the surface of the wood;

- sandpaper with different grit for grinding and final polishing;

- Stains and other tools to create a decorative effect;

- varnish for the final opening of the surface of the product at the end of brushing.

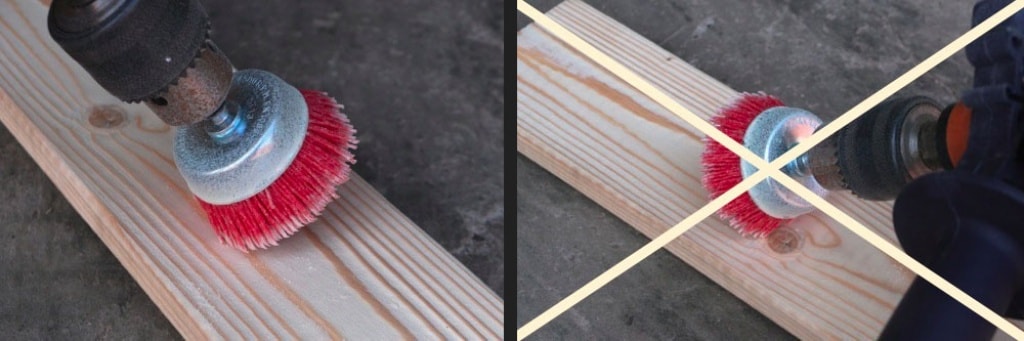

Maximally simplify the work and make them more mechanized will help drills with speed control or machines designed specifically for brushing.

In addition, you should purchase wide or flat brushes of different types: polymer (with abrasive), hair or sesal and metal. Adhering to the correct technique and priority, with the use of mechanical equipment, it is possible to achieve perfect execution of parts for different products.

Brushing technique: step by step

1. So that the dust from the wood does not scatter, the workpiece must be moistened. The first treatment is made with a metal brush. Its rigidity is selected depending on the degree of hardness of the wood. It is important that the bristles do not damage its hard fibers, but it also removes soft fibers well. The trajectory of movement should follow the direction of the fibers, and the speed should be moderate enough for effective scraping.

High rotation speed can bake wood, so you need to be able to select the appropriate option individually for each piece. In the case of manual work, this problem is excluded, but here you will have to put more effort and time.

2. The first grinding of the sample removes scraps and roughness of the fibers remaining on the surface. It is made by a polymer brush with an applied abrasive. After removing all the excess, you can see how well and deeply the structuring was performed, and, if desired, also deepen the resulting grooves. At this stage, you can add decoration with decorative elements. Using a stamestka, in various places it is necessary to mark deepenings of any form. Next, they are rough grinding, after which you can give them the appearance of natural old cracks.

3. Final polishing is done with a hair or sisal brush. At this stage, the product already acquires a glossy finished look, fully revealing the beauty of the decorative texture of wood. Manual processing is performed with emery fine-grained paper, due to which the effect of perfect polishing is achieved. Next, the product is prepared for further staining and varnishing. If at first the wood surface was moistened, then at this stage it should be properly dried and thoroughly cleaned of settled dust.

4. To give a special decorative effect, the product is subjected to a number of additional manipulations - patinated, gilded, painted, fired and other ways of finishing.

Using wood stain, achieve the effect of aging due to the resulting textured contrasting patterns.A special impression is made by the gold paint that fell when applied to small cavities and cracks on a natural wood background. After painting the surface is finally polished, thus getting rid of the roughness that has arisen during the processing of coloring compositions.

Using wood stain, achieve the effect of aging due to the resulting textured contrasting patterns.A special impression is made by the gold paint that fell when applied to small cavities and cracks on a natural wood background. After painting the surface is finally polished, thus getting rid of the roughness that has arisen during the processing of coloring compositions.

5. The last step is varnishing. In this case, the tree must be absolutely clean and dried.

Parquet brushing requires the use of special parquet lacquer. Such coverage will last a long time.

Sphere of use of brushing technique

The availability and stunning decorative effect of the brushing technique make it very popular in the manufacture of interior items and other details in the design of the premises.

Shelves, columns, ceiling beams, wall panels, fireplaces, made of deliberately aged wood, give a special charm and color to the halls and living rooms, kitchens and restaurants.

Wood furniture with brushed elements looks very elegant.

Particularly valuable is the material touched by the bark beetle, since such an invoice is not reproduced manually, and in fact it creates an absolute impression of the antiquity of a wooden product.

The brushing technique is an ideal and affordable way to create a flawless interior with a colorful style of country or vintage. Structured wood objects will fill the house with natural motifs, a special atmosphere of warmth and comfort, will be a highlight in the overall design.